Bellow sealed valves is a kind of a Regulation cum Isolation valve which Regulate & Isolate the pressure & Flow with its compact structure making sure that the leak proof valve helps in avoiding leakages through Valve Body – Bonnet Joint & Gland. Such leakages can lead to:

- Pollution in the environment

- Production loss leading to revenue loss

- Material loss

- Hindrances in the overall processes which reduce the efficiency

- Energy loss which also leads to reduced efficiency of the process

- Dangerous and hazardous for plant employees

Take the case of a steam leakage through the Valve gland as an example. At a pressure of about 150 PSI, a clearance of just 0.001″ through the gland may lead to a leakage of about 25 lb/hour. This leads to a loss of $1.2 per eight-hour shift, or $ 1,100 per year. Similarly, a tiny leakage of 0.4 mm diameter per second results in a waste of about 200 liters per year of expensive oil or solvent. This leakage can be reduced considerably by using the bellow sealed valves .

Even with timely installation, selection, periodic maintenance and check of conventional valves, leakages cannot be eliminated. This problem is solved greatly using bellow sealed valves and hence the demand for the manufacturers and suppliers of bellow sealed valves has risen exponentially.

How Does A Bellow Sealed Valves Operate

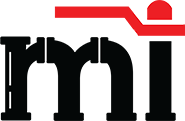

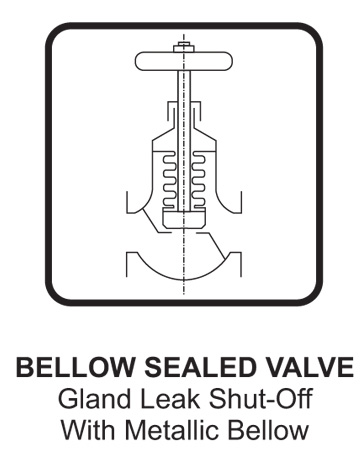

In these valves, conventional gland packing is appended /supplemented by a metallic Bellow Cartridge joined to the valve bonnet at one end, and the stem at the other end.

A bellow is a long accordion-like tube.

As the valve stem strokes, the bellow expands or compresses with the stroke movement. The stem is fully covered with metallic bellow in wet zone, process fluid never reach the gland area. Thus the fluid will enter the valve from the seat of the valve & come in contact with the bellow, but will not come in contact with the stem.

Since the stem is the only moving part in the valve, it is a source of potential leakage through the gland due to constant friction caused by the axial movement. In a bellow sealed valves this potential leak through gland is totally avoided due to the metallic bellow which blocks the leak path effectively by not allowing the media to come in contact with the stem and thus the gland.

A bellow is the heart of this type of valve. There are two types of bellows:

Hydro Formed and Welded leaf.

A Hydro formed bellow is made by rolling a flat metal sheet into a tube with longitudinal fusion welding. This tube is then mechanically or hydraulically formed into bellows with rounded and widely spaced folds.

In Welded Leaf-type Bellows, washer like plates of thin metal are welded together.

We use only Hydro formed bellows, as in spite of being more expensive than welded bellows, their life is many times more than welded bellows.

Why Is Forxar Industries (Valvola) the Best Manufacturer & Supplier Of Bellow Sealed Valves?

We design bellow sealed valves using Hydroformed bellows. Even though it is more expensive than welded bellows, it makes the final product last longer and work better.

At Forxar Industries, we are 100% committed to quality and customer satisfaction.

- Precision finish seat & surface

- Zero Fugitive emission (Class “A”) (Helium Leak Test)

- Fire-safe design

- Suitable for vacuum service

- Easy replacement

- Additional odour and safety measure

Bellow Sealed Valves Applications

These kinds of valves are particularly suitable for pipelines of High Temperature Hot Oil, Thermic Fluid (Santotherm / Dowtherm / Therminol) steam and flammable, explosive and hazardous media. Moreover, because of bellow’s properties of deformation and aging resistance, bellow seal valve overcomes the common latent defects, including temperature sensitivity and the aging of the stuffing box.

Bellow Sealed Valves are specifically used in industries such as Refineries, Natural Gas, LPG & LNG, Synthetic, Paper & Pulp, Chemical, Perto – Chemical, Textile.

It is also used in Industrial plants such as fertilizers, plastics, paints, shipping, rubber, cement.

These industries typically includes all kind Hazardous & Corrosive Chemicals & Heat Transfer Media like high & medium pressure steam, hot oils like Dowtherm, Therminol, Santotherm etc.

It is also used in Hot Water / Condensate etc.

| Valves for Special Application:- |

|---|

| Jacketed Valves |

| Regulating Valves |

| Three-Way Valves |

| Manifold Valves |

| Vacuum Valves |

| Bellow Seal Bellow Operated |

| Cryogenic Valves |

| Needle Valves |

| Valves for Special Application:- |

|---|

| Precision finish seat & surface |

| Zero emission (Class”A”) |

| Fire Safe Design |

| Suitable for vacuum service |

| Easy Replacement |

| Additional Odor & Safety Measure |

FAQs

Bellow Sealed Valves are a new breed of industrial Process valves, designed to eliminate valve leakage and are also known as Zero Leak Valves or Emission Free Valves.

Oil & gas Industry, Nuclear & Thermal Power Industry, Chemical Industry, Food & Pharmaceutical Industry,General Industries.

Losses incurred due to leakages in valve are main consideration in any Industry For e.g. (in a 15 mm valve) Steam at a pressure of 150psi escapes through a gland with a clearance of 0.001 in. at a rate of 25 lb/hr. This translates to a loss of approx $1.2 / 8-hr (Rs. 54 / 8-hr) shift and $1,100 / yr. (Rs. 59,130 / yr.) A tiny drop of 0.4 mm diameter/sec results in a waste of about 200 Ltr. / yr. of costly oil or solvent. That translates to a loss of approx $1,200 / yr.(Rs. 54,000 / yr.) of a commonly used heating fluid like Dowtherm. And all this for $100 valve!!!. (Rs. 4,500 valve!!!.) Apart from this high cost of energy and material loss, the leakage also results in serious environmental, ecological and containment problems. The leaking fluid can be corrosive, inflammable, explosive or poisonous.

At Forxar we are 100% committed to quality and customer satisfaction.

Precision finish seat & surface

Zero Fugitive emission (Class “A”) (Helium Leak Test)

Fire-safe design*

Suitable for vacuum service

Easy replacement

Additional odor and safety measure.

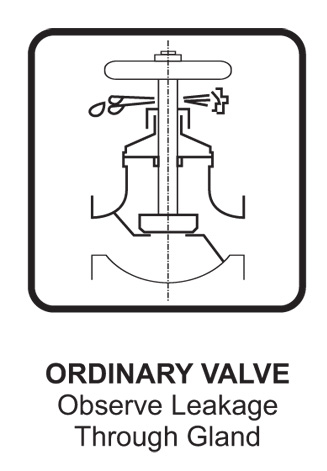

The bellow seal globe valve has superior sealing performance and is more efficient to guarantee the security of pipelines with hazardous media than the stranded globe valve does.

The stranded globe valve is sealed by packing and has the valve stem not in tight contact with packing, causing high leak rates.

But by using bellow seal globe valves we doesn’t have such problem occur in valve from packing, gland stem etc.